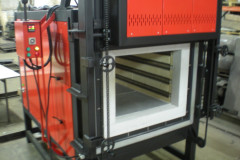

Shaft furnaces

Uterna offers an extensive range of shaft furnaces. The Uterna shaft furnace is used in many technical areas, especially in the automotive, heavy machinery and aviation industry, but also for glass and ceramics.

* Shaft furnaces without air circulation

This furnace system is suitable for temperatures of up to 1300° Celsius and is thus ideal for use in the following areas of application:

– Coarse-grain annealing

– Hardening

– Solution heat treatment

– Normalizing heat treatment

* Shaft furnaces with air circulation

This furnace system is suitable for temperatures of up to 900° Celsius and is thus ideal for use in the following areas of application:

– Tempering

– Precipitation hardening

– Normalizing heat treatment

– Stress relief annealing

– Annealing

* Shaft gas carburising furnaces

This furnace system is suitable for temperatures of up to 1000° Celsius and is thus ideal for use in the following areas of application:

-Carburising

-Carbon nitriding

-Carbonising

* Shaft gas nitriding furnaces

This furnace system is suitable for temperatures of up to 700° Celsius and is thus ideal for use in the following areas of application:

-Nitriding

-Nitrocaburising

Our circulation furnaces are characterised by their stable construction and their reliable functionality over years.

Furnaces are available in all sizes / temperature and with all special equipment

UAB Uterna

Metalo 9, LT - 28217 Utena,

Lithuania / EUROPE

Phone - WhatsApp:+37069813112

E - mail: [email protected]

[email protected]

www.uterna.com

EUROPE made

Automatic Treatment *

Future Technologies new QAA

Latest News

For heat treatment shaft furnaces are used in electrical or gas-heated versions. We supply shaft furnaces for various heat treatment processes up to usable lengths of over 10 m and usable diameters of up to 6 m.

The advantages: it is possible to charge the furnaces directly by crane. Due to the typical recessed furnace shafts only a low crane hook height is required. The vertical treatment of long components minimizes changes of dimensions and shapes. A high heating and cooling rate with a uniform heat transfer to the components is achieved by a convection using circulation and a gas cylinder.

Also different models of tower type melting furnaces with holding capacities from 600 to 5,000 kg and melting capacities from 300 up to 3,000 kg.

The advantages: it is possible to charge the furnaces directly by crane. Due to the typical recessed furnace shafts only a low crane hook height is required. The vertical treatment of long components minimizes changes of dimensions and shapes. A high heating and cooling rate with a uniform heat transfer to the components is achieved by a convection using circulation and a gas cylinder.

Also different models of tower type melting furnaces with holding capacities from 600 to 5,000 kg and melting capacities from 300 up to 3,000 kg.