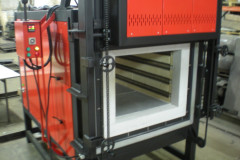

Chamber furnaces

This furnace system is suitable for temperatures of up to 1350° Celsius and is thus ideal for use in the following areas of application:

– Coarse-grain annealing

– Hardening

– Solution heat treatment

– Normalizing heat treatment

– Hardening

– Solution heat treatment

– Normalizing heat treatment

For temperatures above 900℃, circulation is not implemented. The even temperature distribution is ensured via the heating elements attached on multiple sides (3 or 5 sides). The workpiece is more durable with regard to wear and tear. It creates an amorphous state in steel, which is characterised by a particularly high level of hardness. For this purpose, steel is heated to the so-called hardening temperature in accordance with the alloy.

From this temperature, the pieces are cooled as quickly as possible down to room temperature (“quenched”). Depending on material, cooling is carried out by air, oil, polymer or water.

Furnaces are available in all sizes / temperature and with all special equipment

The chamber furnace is the simplest design of an industrial furnace compared to the other furnace types. The main focus here is on the compact design. No additional equipment is required for successful heat treatment.

Chamber furnace, Continuous furnace, Turntable furnace, Bogie hearth furnace, Top loader furnace, Drawer furnace, Hood-type furnace, Stacking furnace, Double rack furnace, Custom furnace

Chamber furnace, Continuous furnace, Turntable furnace, Bogie hearth furnace, Top loader furnace, Drawer furnace, Hood-type furnace, Stacking furnace, Double rack furnace, Custom furnace

UAB Uterna

Metalo 9, LT - 28217 Utena,

Lithuania / EUROPE

Phone - WhatsApp:+37069813112

E - mail: [email protected]

[email protected]

www.uterna.com

EUROPE made

Automatic Treatment *

Future Technologies new QAA

Latest News