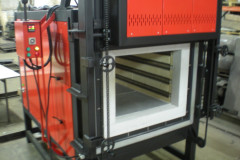

Bogie hearth furnaces

UAB Uterna

Metalo 9, LT - 28217 Utena,

Lithuania / EUROPE

Phone - WhatsApp:+37069813112

E - mail: [email protected]

[email protected]

www.uterna.com

EUROPE made

Automatic Treatment *

Future Technologies new QAA

Latest News

Furnace heat treatment normalizing, preheating, austenitizing, pearliting, ferriting or softening.

From electrically or gas heated melting furnaces, dewaxing furnaces or core drying furnaces to fully automatic annealing plants for aluminum or steal, covers professionally all applications for the foundry industry. Melting and Holding Furnaces melting furnaces Cleaning Furnace for Riser Tubes, Electrically Heated Forced Convection Furnaces Drop-Bottom Furnaces Electrically Heated or Gas Fired Quench and Tempering Plants for Steel Quench Tanks Chamber and Bogie Hearth Furnaces Catalytic and Thermal Post Combustion Systems Continuous Operation Furnaces Temperature Uniformity and System Accuracy AMS 2750 E, NADCAP, CQI-9 Process Control